Skip to content

Processes

Vertical Milling

Vertical Milling- Vertical CNC machining with travels up to 24” x 44”

- including 4th-axis which allows machining multiple sides of a workpiece in one operation

Horizontal CNC Machining

Horizontal CNC Machining- Horizontal machining with:

- High-density fixturing

- Part changing on off-loaded pallet allows the spindle to continuously machine parts

- Simultaneously run several different details by fixturing on different faces and pallets

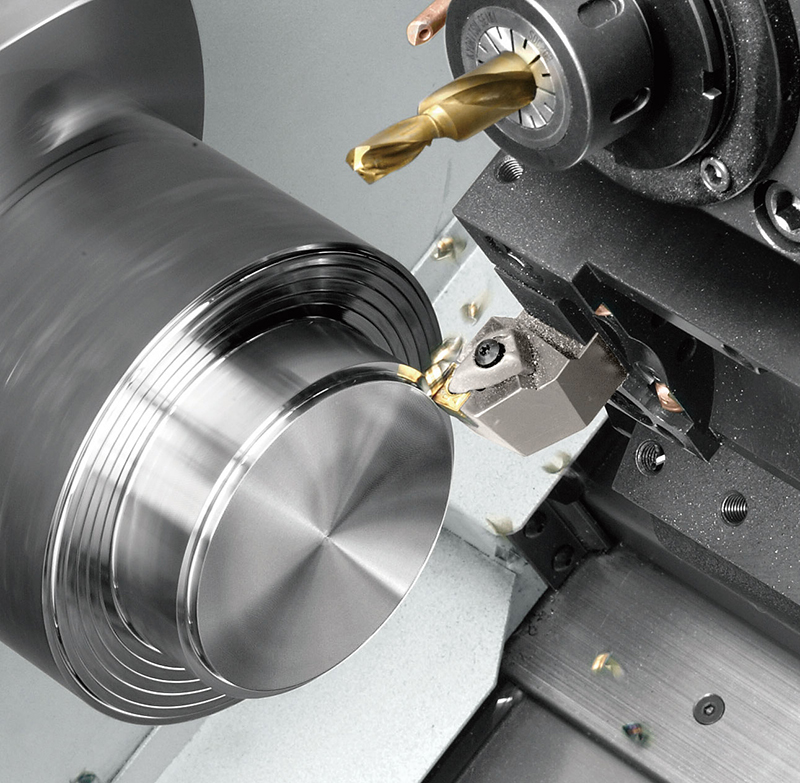

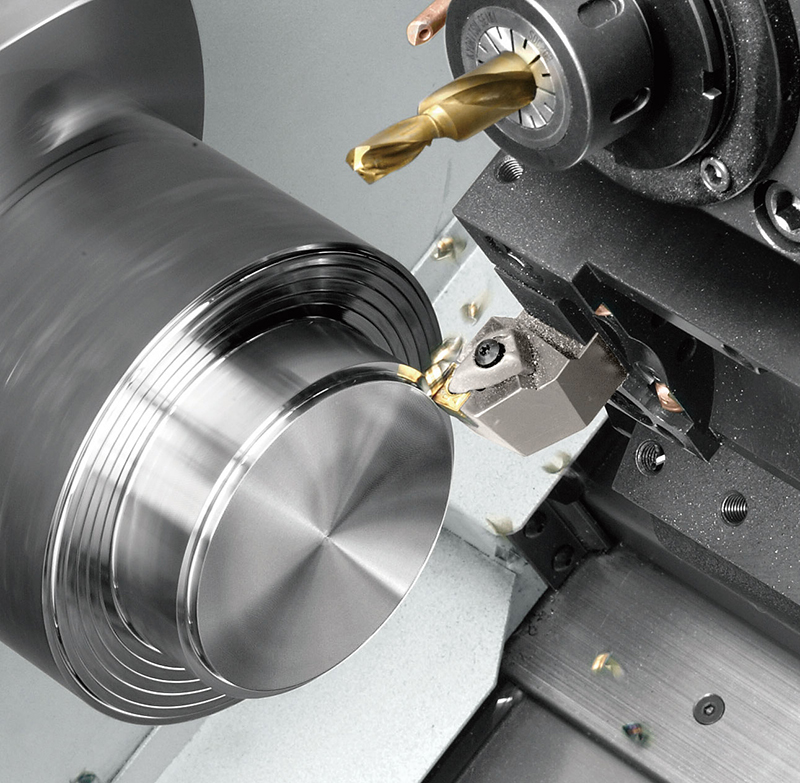

Turning

Turning- Turning up to 12” diameter

INTEGREX Mill Turning Machine

INTEGREX Mill Turning Machine- Mill/Turn done-in-one machining

- Allows complex parts to be made in one operation

- Quick change collet systems on the main and sub spindle enable rapid changeovers

- Bar stock feeder allows extended unattended lights-out operation

Secondary Processes

Secondary Processes- Grinding including CNC contour surface grinding

- Five axis wire EDM with 12” submerged depth

- Vetted sources for heat treat, plating, etc.

Materials

- Steels including HRS, CRS, low carbon, Fre-Max, 4140, 8620 and others

- Stainless steels 300 series, 400 series, 17-PH and others

- Tool steels including O1, A2, D2, D6, S7 and others

- High speed tool steels including M2, M4, CPM-10V, CPM-15V and others

- Super alloys such as titanium and Inconel

- Carbide

- Aluminum 6061, 7075, MIC-6, Fortal and others

- Plastics of all types

- Other materials including rubber and wood